Digital Printing

Direct to Garment Printing (DTG)

During DTG printing a digital image is printed straight onto the product, using the newest technology of garment printing. This process allows printing high quality full colour image straight to the fabric without making printing frames which makes producing single units and small batches faster and cheaper.

Digital printing allows designs that are too complex for traditional printing methods – it enables printing noticeably more detailed images compared to, for example, silk screen printing.

Technology

Digital printing machine is actually an inkjet printer which instead of a paper prints directly on textile.

After your confirmation of the final design we will put together a printing file. Not any kind of image file, as opposed to a regular ink printer, can be printed with this printer. To make the image transfer to the fabric in the desired way, it is necessary to determine the amount of ink, the color of the base fabric and the image’s location on the plate before printing.

If the file is ready for printing, the product is placed in the printer on a special rough-textured plate which keeps the product from moving during printing. Because the print head doesn’t come into contact wit the product and instead sprays ink onto the surface from a small distance, it is possible, as opposed to silk screen printing, to print designs over pockets, seams and zippers. Neither lining or a thick or multilayered fabric interfere with printing as the distance of the print head from the garment can be adjusted. Even then, the product shouldn’t have too far-protruding parts as the closer the print head is to the garment the better the result will be.

In the case of coloured fabrics, the printable area is covered with pretreatment solution beforehand to stop the excessive soaking of the ink into the garment and to ensure brighter colours in the final result. As the printer inks are translucent, to get the colour tones right on the coloured garment, a white layer needs to be printed underneath, followed by the coloured image on top. For that reason, printing on coloured garment is more work-intensive and slightly more expensive.

Final curing process takes place in a tunnel dryer where the ink binds and achieves washing and fading resistance.

Which products are suitable for direct to garment printing?

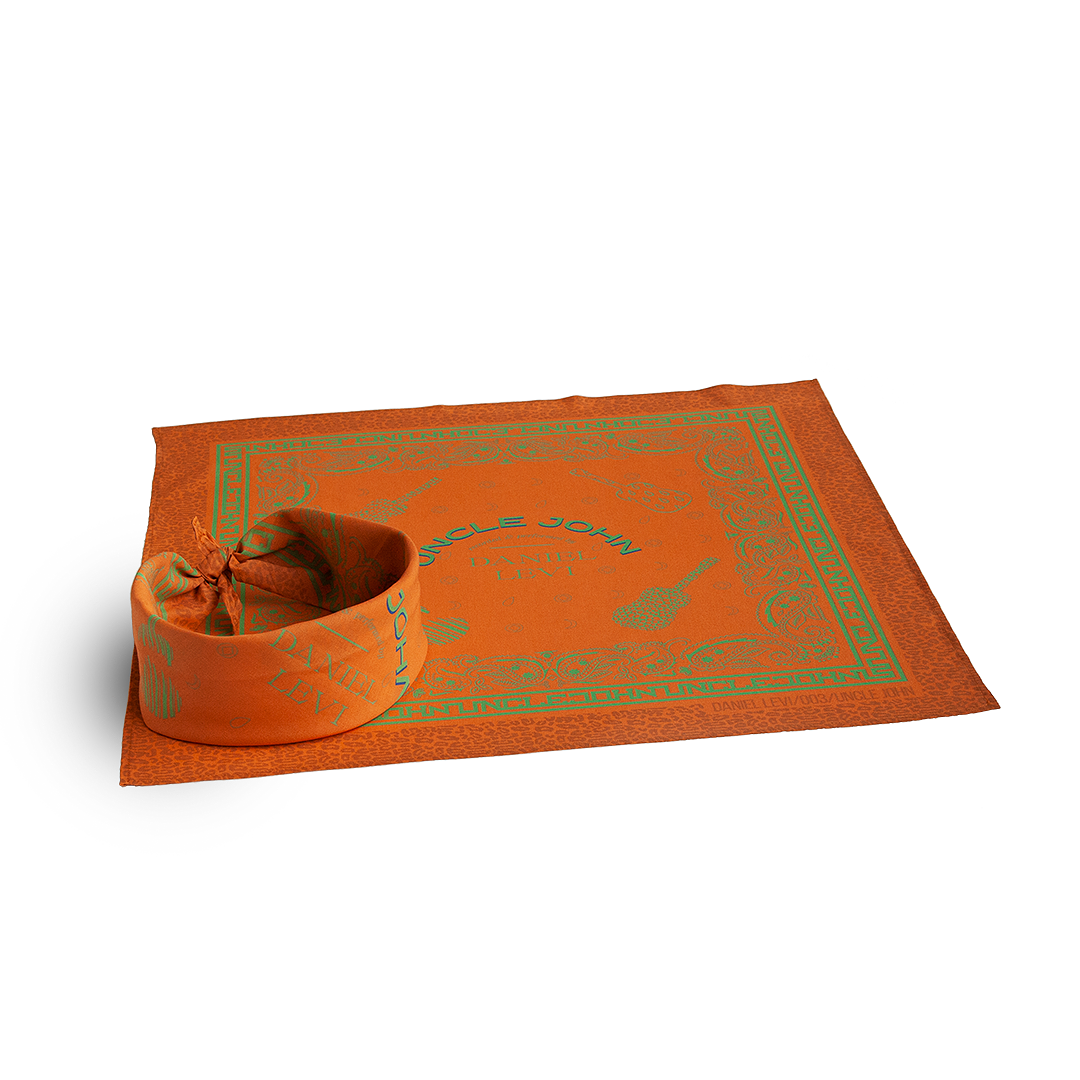

DTG printing can be used for a variety of products that consist of 100% cotton, or cotton with up to 20% of polyester or elastane: t-shirt, sweaters, hoodies, bags, towels, etc. Water based inks are suitable for printing on children’s clothes. Digital print is almost as wash proof as a silk screen print.

The final result depends largely on the product itself. For a smoother surfaced fabric, the print will be more detailed and in higher quality.

How to place an order for digital printing?

Send us your design (suitable file format is .png, 1:1 size with a resolution of 300 ppi). We will review it and put together a price estimate. If you don’t have a suitable file, we can also help with a design service or convert other image or vector files into suitable files for printing. Maximum print size we offer is 355 x 406 mm.

To calculate the price, we will need the following:

- The quantity of products

- The size of the printable design (A5, A4, A3)

- Whether the fabric is white or coloured